Visiflon

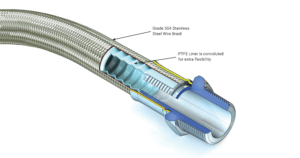

HOSE CONSTRUCTION

Visiflon was previously named Hyperline V – either name applies, but Visiflon is now the conventional name applied.

Visiflon includes a helically convoluted PTFE liner tube, and the tube is fully convoluted inside and out. (This is different to Hyperline FX tube, which is only convoluted on the outer surface).

This convoluted liner design makes the hose very flexible and very kink resistant across the size range.

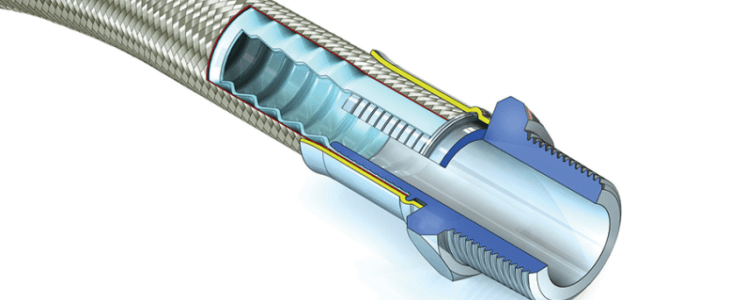

Visiflon Hose Assembly with a Fixed Male End Fitting crimped on to the hose

Standard Grades Available

Visiflon GP, TO – Natural PTFE Tube Only, No Braid.

Visiflon GP, AS, TO – Antistatic Black PTFE Tube Only, No Braid.

Visiflon GP, SS – Natural PTFE Tube external AISI 304 Stainless Steel Wire Braid.

Visiflon GP, AS, SS – Antistatic Black PTFE Tube, external AISI 304 Stainless Steel Wire Braid.

*Visiflon GP, PB – Natural PTFE Tube, Orange Polypropylene Yarn Braid.

*Visiflon GP, AS, PB – Antistatic Black PTFE Tube, Orange Polypropylene Yarn Braid.

Grade Descriptions

Antistatic PTFE Linings (AS Grade)

When electrically resistive fluids like solvents and fuels, or multiphase mixtures are passed through natural PTFE hose at high flow rates, a static charge build up occurs on the inner wall of the PTFE liner, which eventually discharges to the nearest earth creating a leak path through the liner.

Antistatic PTFE includes a small quantity of a special carbon black which ensures safe static charge dissipation, in accordance with International Standards.

Stainless Steel Wire Braid (SS Grades)

The braid protects the PTFE liner tube against internal pressure and mechanical abuse.

Polypropylene Yarn Braid (PB Grades)

The braid is lighter in weight than SS braid, and any ends broken in service will not cut an operator’s hands.

Operating Temperatures & Pressures, however are limited.

*Note: PB Grades are usually only available to Special Order.

PROPERTIES

Temperatures and Pressures:

Visiflon TO Grades – The MWP listed above applies up to a maximum temperature of 100˚C (212˚F).

Visiflon SS Grades – The MWP listed above should be reduced by 1% for each 1˚C above 130˚C up to a maximum of 230˚C (1% for each 1.8˚F above 266˚F up to a maximum of 445˚F).

Visiflon PB Grades – The MWP listed should be reduced by 5% for each 1˚C above 80˚C up to a maximum of 100˚C (5% for each1.8˚F above 176˚F to 212˚F).

Vacuum Resistance:

Visiflon SS Grades are vacuum resistant to -0.9 bar up to 130˚C (266˚F).

Visiflon TO and PB Grades are vacuum resistant to -0.9 bar up to 80˚C (176˚F).

Flow Rates:

The internal convolutions restrict flow rates due to turbulent flow, and may also cause a whistling noise when gases are passed through. For any applications where this may be a problem, the alternative Aflex Hose products Hyperline FX or Corroline would provide a solution.

SPECIFICATIONS AND PROPERTIES

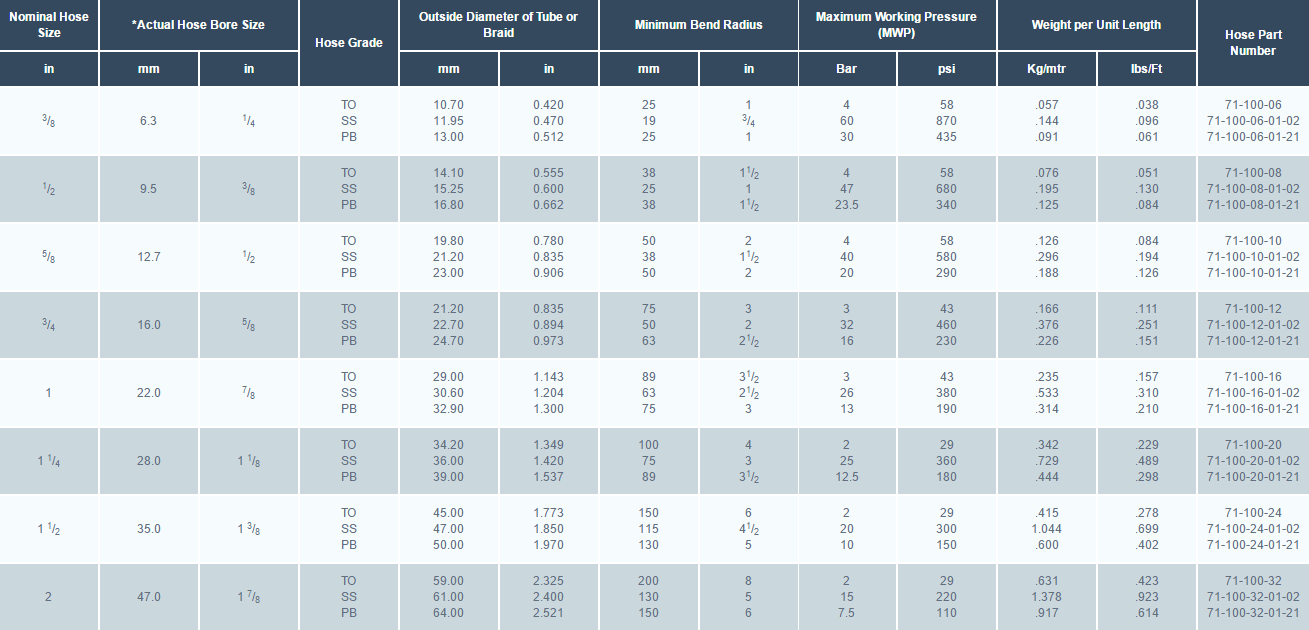

Specifications for Visiflon Hose Grades

*Visiflon Hose assemblies require that the convolutions at the ends of the hose are opened out to accept either Hydraulic or PTFE Tail end fittings (see Assembly Instructions).

Note: Many of the sizes of hose and fittings listed in this brochure are available as ex-stock items and are priced accordingly. However, some of the less popular items are not always in stock, and may therefore incur a minimum order charge or a set-up charge for smaller quantities. Aflex Hose will advise when the enquiry is made.

SPECIAL USAGE CONDITIONS

PTFE Hose-Use with Alkali Metals, Halogens and Halogen containing Chemicals

PTFE hose liners react chemically with Fluorine, Chlorine Trifluoride and molten Alkali Metals.

When PTFE lined hose is used to carry Chlorine or Bromine, either as gasses or fluids, they will diffuse into and through the PTFE liner wall thickness. Trace quantities will then combine with atmospheric moisture to corrode any braid/rubber outer coverings.

Heavily halogenated chemicals, like Hydrogen Fluoride, Hydrogen Chloride, Phosgene (Carbonyl Chloride) Carbon Tetrachloride and other organic chemicals with a high halogen content can also be absorbed and transmitted through the PTFE liner tube.

Other “Penetrating” Fluids and Gases

Sulphur Trioxide, Methyl Methacrylate, Caprolactam and Glacial Acetic Acid are some other chemicals which can be absorbed and transmitted through the PTFE liner tube wall.

Generally, however, as a hydrophobic (non-wetting) material, PTFE is very resistant to the absorption of chemicals. In some cases, PTFE has superior resistance to diffusion, for example to the diffusion of automotive fuels, in comparison with all other plastics and rubbers.

Gas/Fluid Cycling

There are some applications where the fluid passing through the hose turns into a gas, then back into a fluid, then into a gas etc, in a cyclic sequence.

This is normally associated with changes in temperature and/or pressure. For complex reasons these conditions are extremely damaging to the hose liner, whatever material it is made from.

For example, hoses are sometimes used to pass steam, water, steam etc into rubber moulding presses, in order to heat the mould, then rapidly cool it before reheating in the next cycle. Hoses of all types fail rapidly in such an application and PTFE lined hoses are no exception.

Please contact Aflex Hose for further information if these conditions apply.

Connecting Assemblies for Use in Applications

The lengths of hose assemblies and their configuration in use when connected into the application must always be in accordance with the Hose Configuration information at the end of this product literature.

When being connected for use in applications, the end fittings on hose assemblies must be connected to correct mating parts in the correct way, using the correct tools, spanners, clamps, nuts and bolts etc. The connections must be sufficiently tightened to ensure that the joint is leak free but not be over tightened as this can damage the sealing surfaces.

In applications involving the transfer through the hose of expensive or dangerous fluids or gases, the hoses and connections must be pressure tested in situ before being put in to service. This should be done with some harmless media to 2.0 times times the maximum working pressure of the hose assembly, as stated in the product literature.

If in doubt please contact Aflex Hose for advice.

Special Applications

Aflex Hose PTFE lined hose products are not rated as suitable for use in the following, special applications:

- All Radioactive Applications involving high energy radiation, including Gamma radiation (degrades PTFE)

- All Medical Implantation Applications.

- All Aerospace Applications.