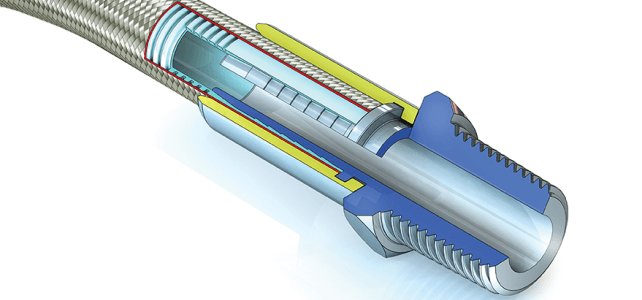

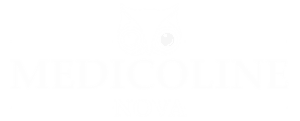

There is a fundamental problem with larger sizes of standard, smooth bore PTFE hose products – as the hose size increases above 1/4”, so smooth bore PTFE lined hose become significantly less flexible, and more easily kinked.

One solution is to use a conventional convoluted PTFE lined hose, but the internal convolutions make the hose difficult to assemble, and reduces fluid flow rates due to turbulent flow.

Hyperline FX is a new and revolutionary solution to all these problems, providing a unique and patented hose liner design which is flexible in the larger bore sizes, yet which retains a smooth bore.

The advantage of a smooth bore as compared with a convoluted bore is that it is easy clean, and does not create “turbulent flow”, which drastically reduces fluid flow rates.

Hyperline FX, SS Hose Assembly with a Hydraulic Fixed Male End Fitting

crimped on to the hose

Standard Grades Available

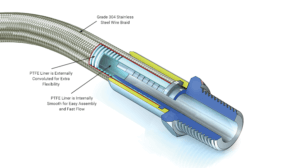

Hyperline FX, TO – Natural PTFE Tube Only, No Braid.

Hyperline FX, AS, TO – Antistatic Black PTFE Tube Only, No Braid.

Hyperline FX, SS – Natural PTFE Tube external AISI 304 Stainless Steel Wire Braid.

Hyperline FX, AS, SS – Antistatic Black PTFE Tube, external AISI 304 Stainless Steel Wire Braid.

Hyperline FX, AM – Natural PTFE Tube, Black Aramid Fibre Braid.

Hyperline FX, AS, AM – Antistatic Black PTFE Tube, Black Aramid Fibre Braid.

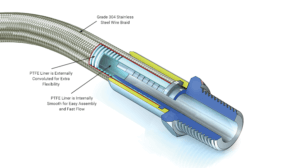

Hyperline FX, SS

Hyperline FX, SS

Grade Descriptions

Antistatic PTFE Linings (AS Grade)

When electrically resistive fluids like solvents and fuels, or multiphase mixtures are passed through natural PTFE hose at high flow rates, a static charge build up occurs on the inner wall of the PTFE liner, which eventually discharges to the nearest earth creating a leak path through the liner.

Antistatic PTFE includes a small quantity of a special carbon black which ensures safe static charge dissipation, in accordance with International Standards.

Stainless Steel Wire Braid (SS Grades)

The braid protects the PTFE liner tube against internal pressure and mechanical abuse.

Aramid Fibre Braid (AM Grades)

The aramid fibre is “Tecnora”, a higher specification fibre than Kevlar, with excellent temperature, tensile and abrasion resistant properties.

For applications requiring minimum weight for maximum pressure reinforcement.

Temperatures and Pressures

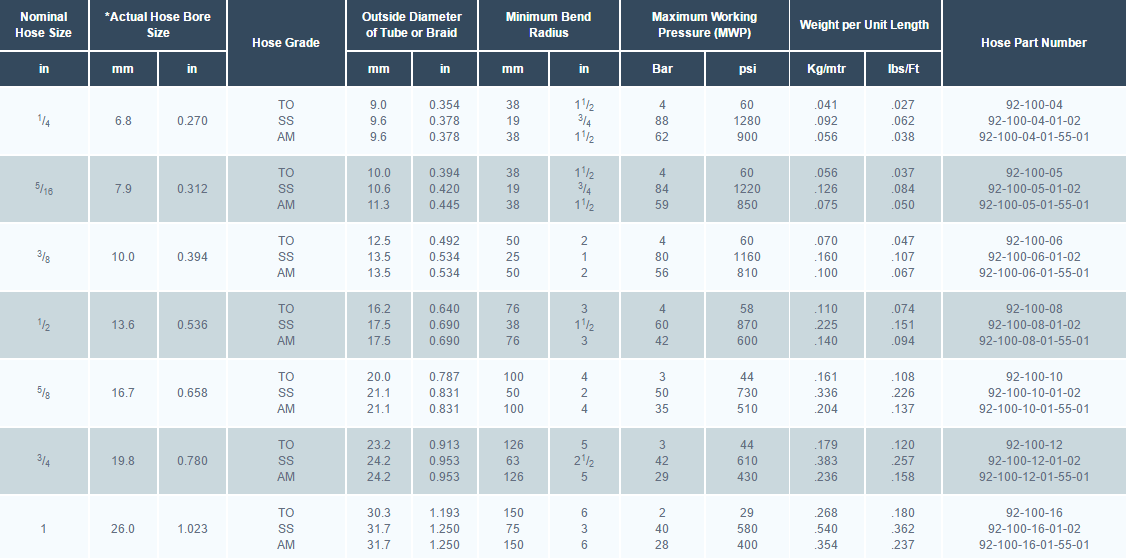

- The MWP listed above should be reduced by 1% for each 1˚C above 160˚C (1% for each 1.8˚F above 320˚F) up to a maximum of 260˚C (500˚F).

- The MWP listed above should be reduced by 1% for each 1˚C above 130˚C (1% for each 1.8˚F above 266˚F) up to a maximum of 180˚C (356˚F).

listed are calculated on the basis of a 3:1 safety factor relative to the burst pressure, so Burst Pressure = 3 x MWP. If MWP is required based on a 4:1 safety factor (e.g. EN 16643 requirement), multiply the listed value by 0.75.

Vacuum Resistance

Hyperline FX, SS Grades are vacuum resistant to -0.9bar up to 130˚C (266˚F).

Excellent Flow Rates

Compared with conventional convoluted hose designs, Hyperline FX has excellent flow rates due to the smooth bore, which prevents the turbulent fluid flow which occurs in convoluted hose products.

Reduced Diffusion Rates

Hyperline FX is much more resistant to diffusion of liquids or gases than other PTFE hose products, due to its highly compressed, non-porous PTFE matrix. Hyperline FX has been successfully tested to SAE J1737 for resistance to automotive fuel diffusion.

Non-Stick Internal Surface

Hyperline FX hose has a smooth bore, non-stick liner which is effectively “self-cleaning”, and which resists material build-up inside the hose which may cause bore constriction.

Loose Hose Lengths

Loose hose is supplied in random lengths up to a maximum of 18 metres (60 feet) long.

Assembled Hose Lengths

Hyperline FX hose assemblies are made up to the specific lengths required. The hose length is taken as the length from the sealing face at one end of the hose to the same at the other end. The length tolerance is normally +2% / -0%. Closer tolerances are available to special order.

Alternative Design Options – Hose Covers

For certain applications, it is an advantage to have a flexible plastic or rubber outer cover extruded on to the hose. The cover provides protection for the braid, as well as being easy to clean, and can be printed with a continuous text line.

Covered hose is, however, only available to special order, so price and availability are very dependent upon quantities required.

Options are:

- Flexible PVC – from -10˚C (+14˚F) to +60˚C (+140˚F) max. In transparent or a wide variety of solid or translucent colours.

- Nylon 11 – from -40˚C (-40˚F) to +120˚C (+248˚F) max. In natural, semi-transparent or black.

- Sarlink, Hytrel, Polyurethane – from -40˚C (-40˚F) to +125˚C (+257˚F) max. Others may also be available.

- EPDM Rubber – from -40˚C (-40˚F) to +140˚C (284˚F) max. In Blue or (antistatic) Black.

- Silicone Rubber – from -73˚C (-100˚F) to +204˚C (400˚F) max. Peroxide cured, in natural (semi-transparent) or white.

Other rubbers may also be available.