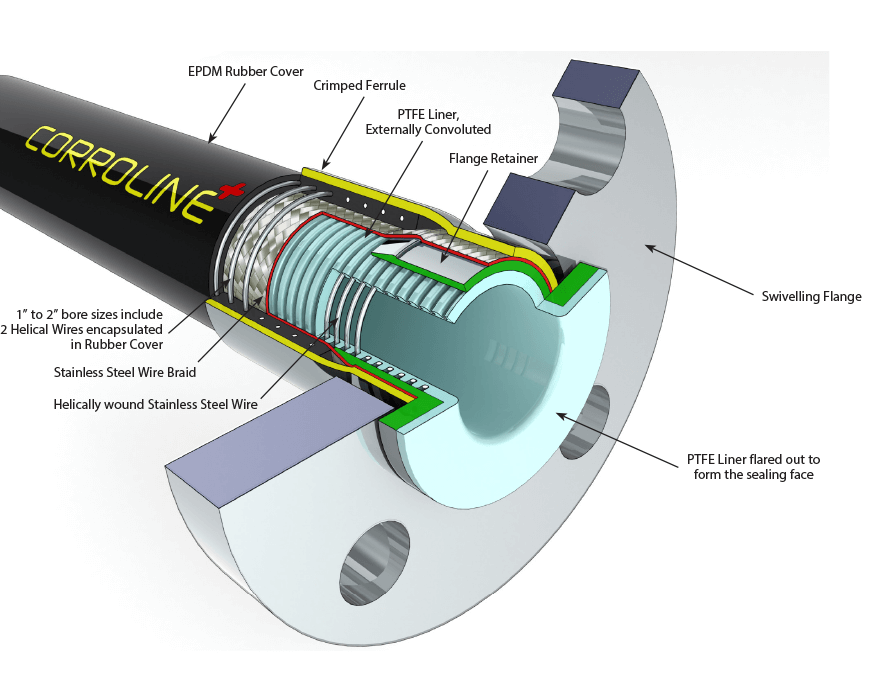

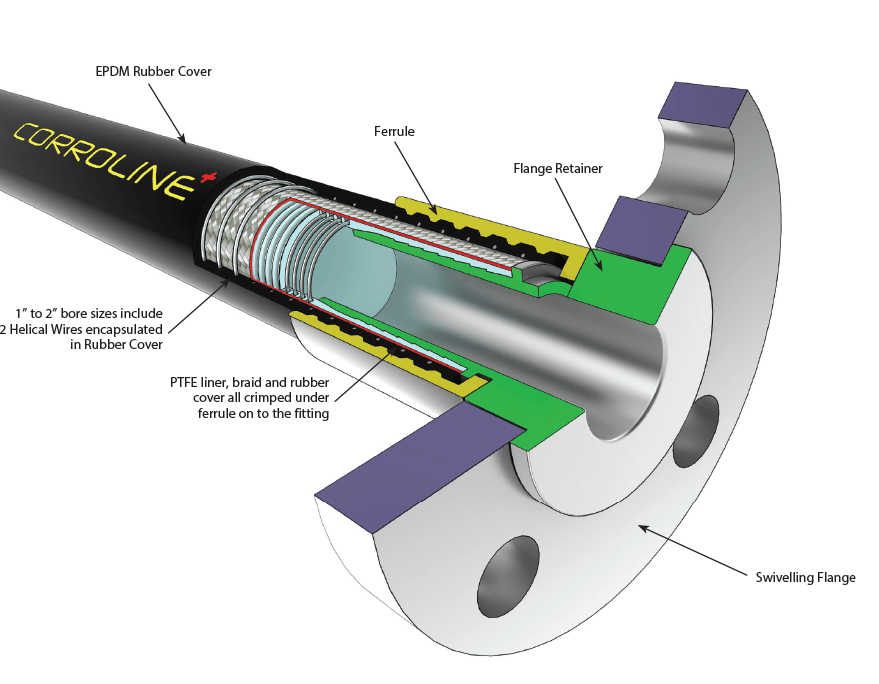

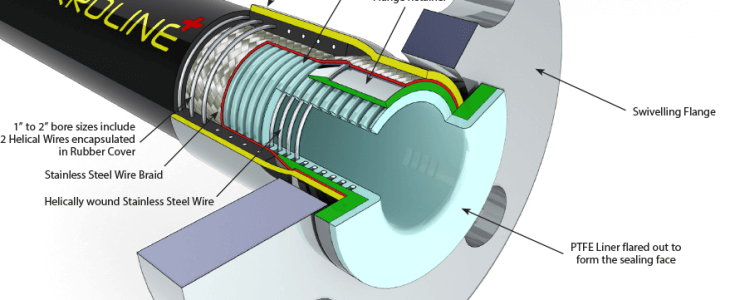

Like Bioflex Ultra, Corroline+ hose is designed to fulfil all the requirements for use as a chemical hose or industrial hose, but with the added benefit that it has been reinforced to withstand the most severe conditions of physical abuse. Corroline+ is as crush proof and kinkproof as a flexible hose can be, because it is recognised that applications exist in chemical and general process fluid plants where such usage conditions apply.

Introduction

Corroline+ hose was designed and developed to provide customers with a universal chemical hose product which combined all the requirements they had requested for chemical plant applications, particularly the need for improved flexibility and kink resistance.

Corroline+ hose provides a superior alternative to the wide variety of alternative Chemical Hose products currently available.