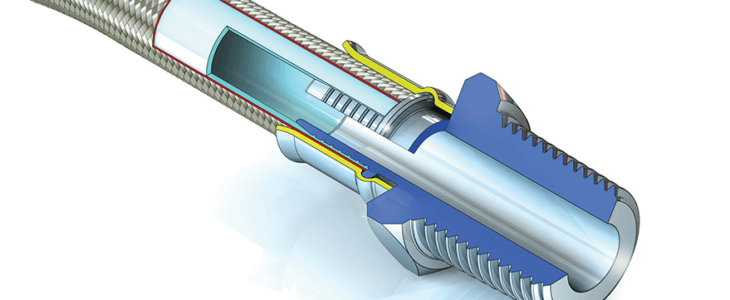

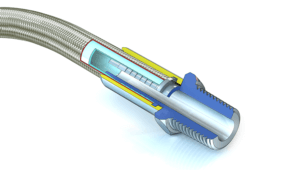

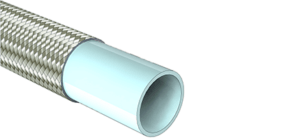

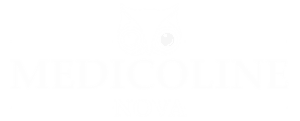

Hose Liner

Seamless extruded PTFE tube. The extrusion, heat treatment and quality control programmes are designed to produce the best quality PTFE tube possible, ensuring minimum porosity and maximum flexibility.

Hose Braid:

Braided from AISI grade 304 stainless steel wire, bright hard drawn to a minimum 1700 N/mm2 tensile strength. The braiding process is closely controlled to ensure even tensions and the correct braid angle, to give minimum expansion/contraction under pressure.

Grades available, and applications

There are 3 standard grades available, with a Single SS wire braid (SB) or a Double wire braid (DB).

Single Braid is suitable for applications in general. Double Braid is required for higher pressures and increased kink resistance.

Grade SW, SB – Standard Wall, Single Braid (or DB, Double Braid)

For general purpose use, including high and low pressure steam, chemicals, paints, inks, adhesives, brake fluids, fuels, oils, detergents, refrigerants and foodstuffs.

PTFE lined hose is the optimum hose product wherever excellent chemical resistance, temperature resistance and/or internal “non-stick” cleanability are primary requirements of the application.

Grade HW, SB – Heavy Wall, Single Braid (or DB, Double Braid)

For heavy duty use, also for use with gases up to 100 Bar pressure, and for hot/cold cycling applications.

Grade MW, SB – Medium Wall, Single Braid, also called Hyperline SB (or DB, Double Braid)

The Hyperline name is applied to Aflex PTFE hose products which have an oversize bore, to enable assembly with standard Hydraulic End Fittings. In most cases, these sizes are the same as the conventional “dash” hose size range, as indicated in the specifications.

High Pressure Gas (HPG Grade) PTFE Tube Liners

Available to Special Order Only

For applications where gases are used in the hose at high pressures, or testing procedures above 100 bar (1500 psi) it is necessary to specify an HPG grade PTFE liner tube. HPG grade is also required when high pressures are applied to “penetrating” fluids.

HPG grade tubing is achieved by subjecting the PTFE tube to certain special processes, commonly known as “post sintering”, which increases the resistance of the material to penetration and porosity development by gases in service.

HPG Specification

This specification requires that when compressed air or nitrogen is applied to a sample length at a pressure of 275 Bar (4000 psi) for 1 minute, then the pressure rapidly broken then re-applied for a total of 10 cycles, the sample must not show signs of excessive diffusion when finally gas tested under water.

Because pure gases do not generate static charges, HPG liners are rarely required to be antistatic, but on such rare occasions, a special “inner layer” AS grade is used as described at the bottom of this page.

Note: All sizes and types of Smoothbore Hose PTFE tube liners can be supplied to HPG quality.

In practice, however, HPG hoses are nearly always HW (Heavy Wall) grade, in bore sizes from 6mm (1/4”)

up to 10mm (3/8”)

Anti-Static (AS Grade) PTFE Tube Liners

Available to Special Order Only

Purpose

An AS Grade PTFE tube liner is an essential requirement in applications where there is a risk of an electrostatic charge build-up on the inside surface of the PTFE tube which may then discharge through the tube wall. Media passing through which create such a risk are fluids which have a Conductance of less than 10-8 S/m (Siemens per Metre), or 104 pS/m such as fuels, solvents, freons, some oils, some WFI (ultra-pure “Water for Injection”) and non-polar organics which are being transferred at a medium to high flow velocity (more than 2 mtrs/sec.)

All twin or multi phase media, and any non-mixing media, such as powder in air, or water droplets in steam, in gases or in oil, also colloidal fluids constitute a particular hazard for static charge generation, and always require grade AS.

Design & Approval

Aflex Hose AS Grade PTFE tube liners are manufactured from FDA 21 CFR 177.1550 approved PTFE, and less than 2.5% of “high purity” Carbon Black material to FDA requirement 21 CFR 178.3297. The carbon is encapsulated by the PTFE, and in normal, non-abrasive applications will not come loose to contaminate any fluid passing through. Leachables and Extractables testing has confirmed that no loose carbon was found.

HPG/AS Grade Liner

The carbon is mixed into the PTFE for the whole wall thickness of the tube, EXCEPT for rare applications where both HPG and AS are required. For such HPG/AS grade tubes, only an inner layer of the wall thickness is AS grade PTFE, with the outer layer in natural PTFE (see drawing).

PTFE Hose-Use with Alkali Metals, Halogens and Halogen containing Chemicals

PTFE hose liners react chemically with Fluorine, Chlorine Trifluoride and molten Alkali Metals.

When PTFE lined hose is used to carry Chlorine or Bromine, either as gasses or fluids, they will diffuse into and through the PTFE liner wall thickness. Trace quantities will then combine with atmospheric moisture to corrode any braid/rubber outer coverings.

Heavily halogenated chemicals, like Hydrogen Fluoride, Hydrogen Chloride, Phosgene (Carbonyl Chloride) Carbon Tetrachloride and other organic chemicals with a high halogen content can also be absorbed and transmitted through the PTFE liner tube.

Other “Penetrating” Fluids and Gases

Sulphur Trioxide, Methyl Methacrylate, Caprolactam and Glacial Acetic Acid are some other chemicals which can be absorbed and transmitted through the PTFE liner tube wall.

Generally, however, as a hydrophobic (non-wetting) material, PTFE is very resistant to the absorption of chemicals. In some cases, PTFE has superior resistance to diffusion, for example to the diffusion of automotive fuels, in comparison with all other plastics and rubbers.

Gas/Fluid Cycling

There are some applications where the fluid passing through the hose turns into a gas, then back into a fluid, then into a gas etc, in a cyclic sequence.

This is normally associated with changes in temperature and/or pressure. For complex reasons these conditions are extremely damaging to the hose liner, whatever material it is made from.

For example, hoses are sometimes used to pass steam, water, steam etc into rubber moulding presses, in order to heat the mould, then rapidly cool it before reheating in the next cycle. Hoses of all types fail rapidly in such an application and PTFE lined hoses are no exception.

Please contact Aflex Hose for further information if these conditions apply.

Connecting Assemblies for Use in Applications

The lengths of hose assemblies and their configuration in use when connected into the application must always be in accordance with the Hose Configuration information at the end of this product literature.

When being connected for use in applications, the end fittings on hose assemblies must be connected to correct mating parts in the correct way, using the correct tools, spanners, clamps, nuts and bolts etc. The connections must be sufficiently tightened to ensure that the joint is leak free but not be over tightened as this can damage the sealing surfaces.

In applications involving the transfer through the hose of expensive or dangerous fluids or gases, the hoses and connections must be pressure tested in situ before being put in to service. This should be done with some harmless media to 11/2 times the maximum working pressure of the hose assembly, as stated in the product literature.

If in doubt please contact Aflex Hose for advice.

Special Applications

Aflex Hose PTFE lined hose products are not rated as suitable for use in the following, special applications:

- All Radioactive Applications involving high energy radiation, including Gamma radiation (degrades PTFE)

- All Medical Implantation Applications.

- All Aerospace Applications.

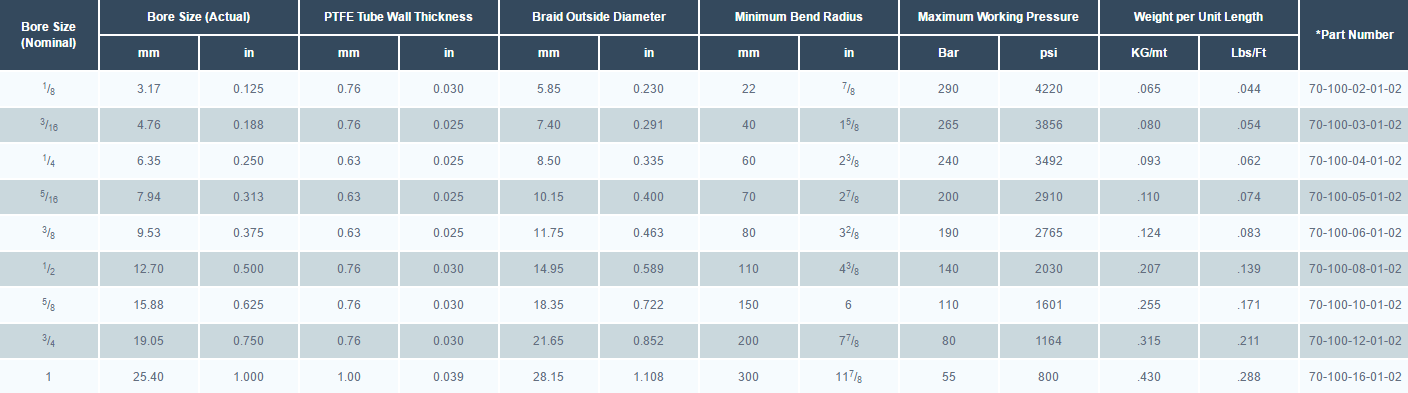

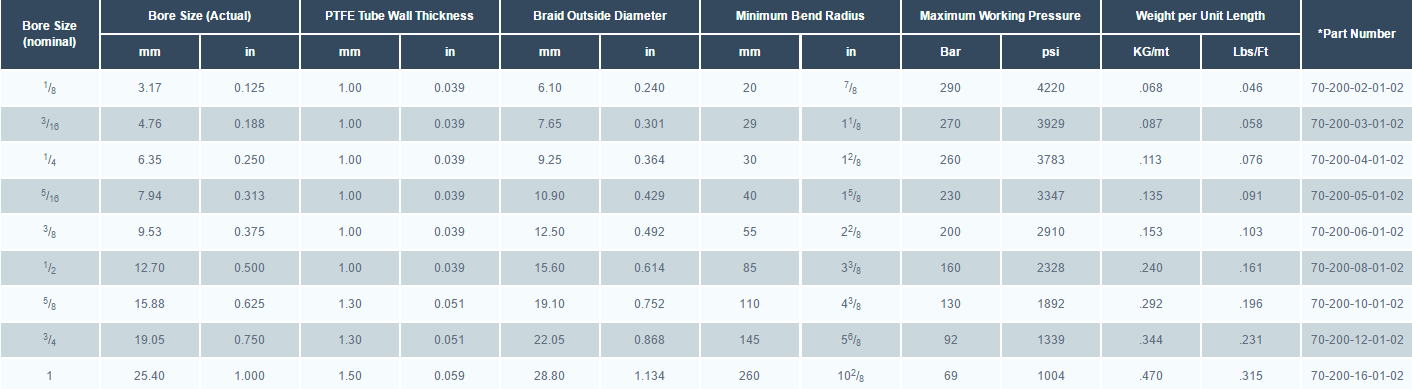

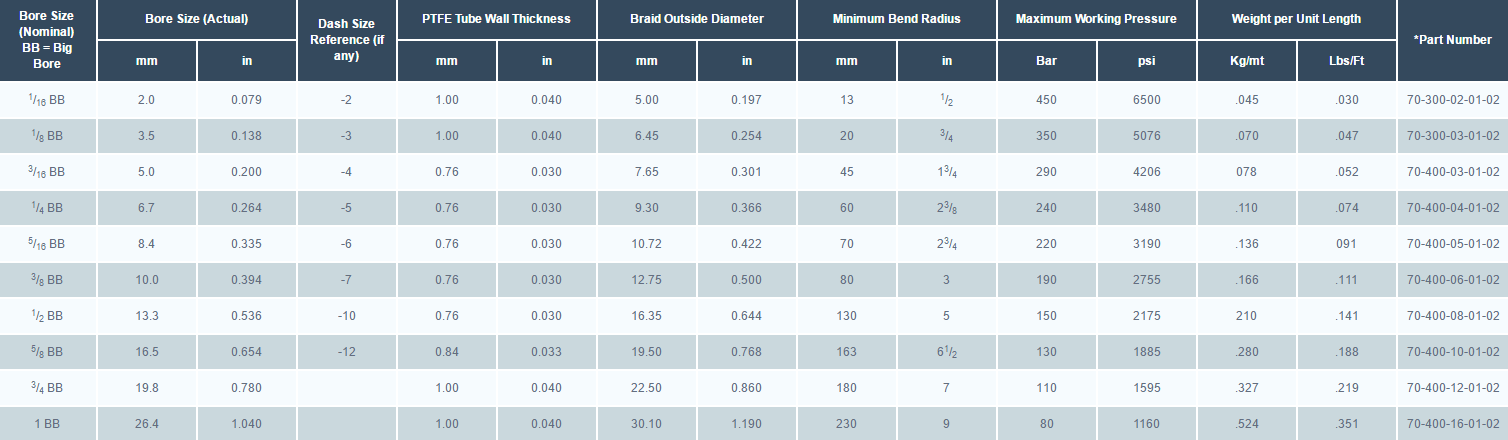

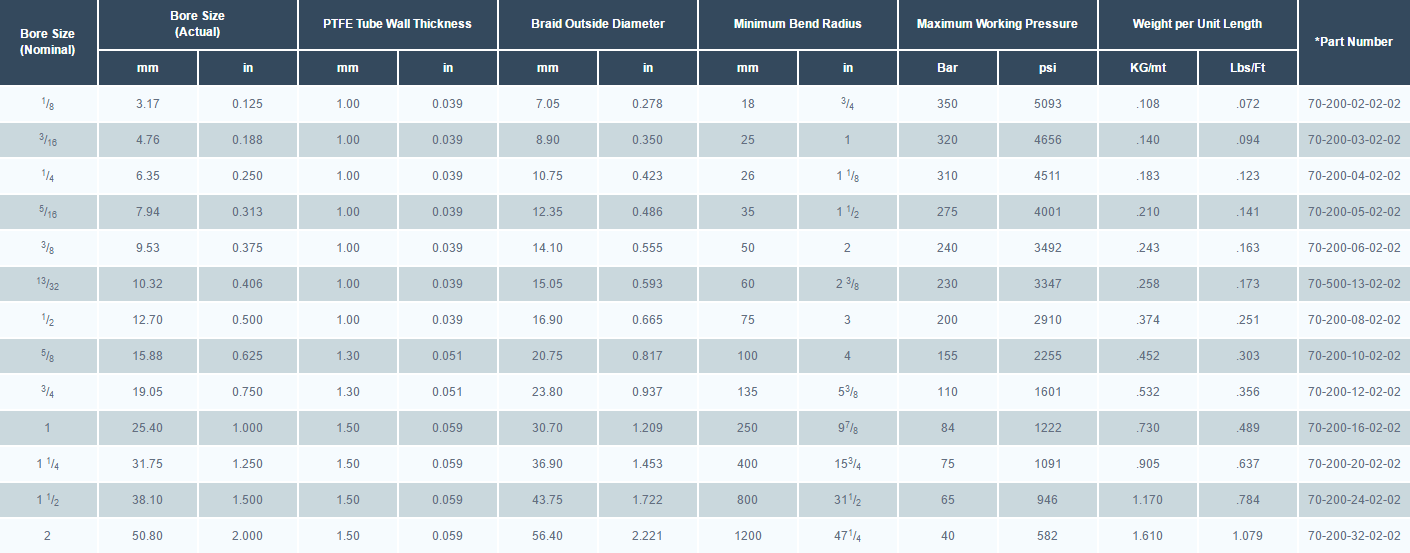

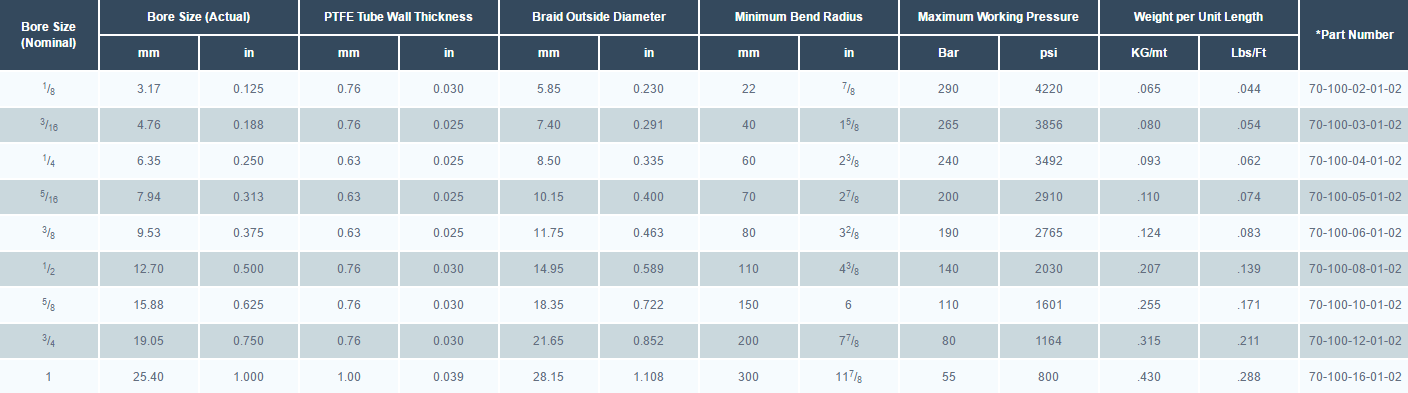

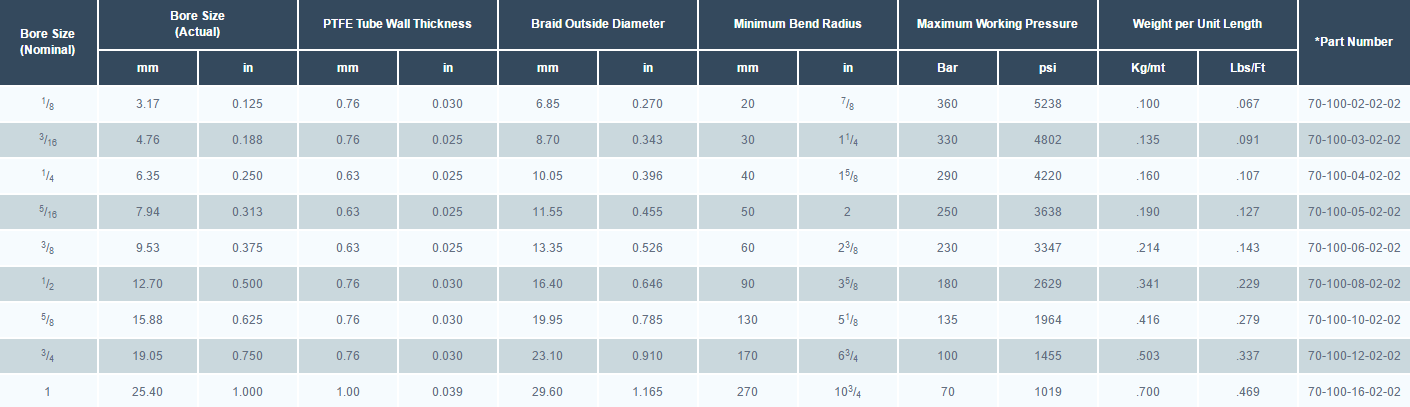

SINGLE BRAID HOSE

Specifications and Size Range

For Single Stainless Steel wire braid hose, for Standard Grade and AS Grade

Standard Wall, Single Braid (SW,SB)

Heavy Wall, Single Braid (HW, SB)

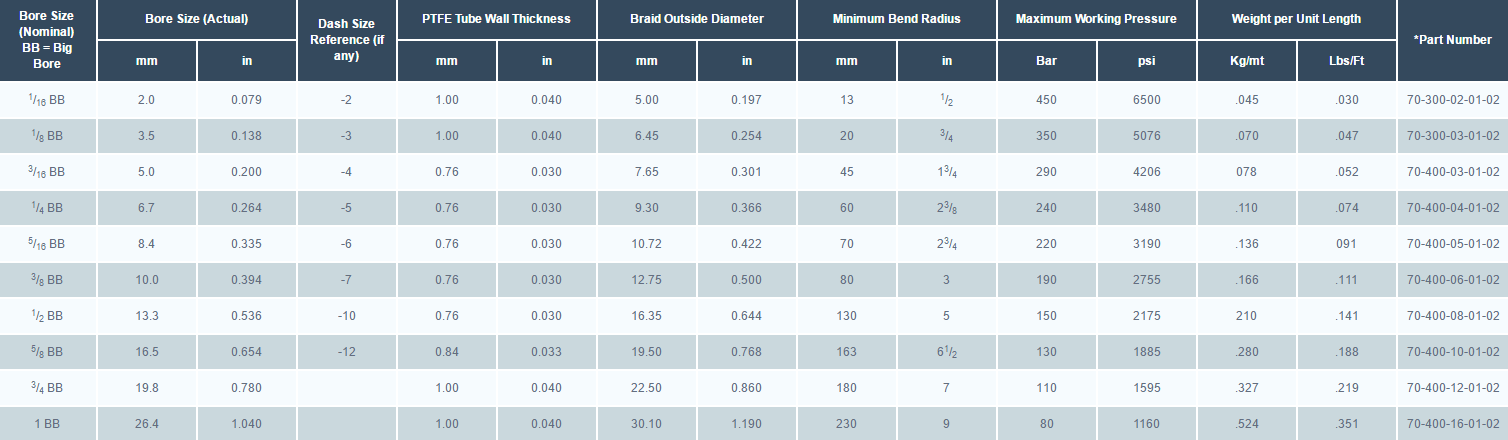

Medium Wall Single Braid (MW, SB), also referred to as Hyperline SB

The Hyperline MW, SB Range meets or exceeds SAE 100R14 standard.

* For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110

Note: Many of the sizes of hose and fittings listed above are available as ex-stock items and are priced accordingly. However, some of the less popular items are not always in stock, and may therefore incur a minimum order charge or a set-up charge for smaller quantities. Aflex Hose will advise when the enquiry is made

Temperature & Pressure

Temperature affects the Maximum Working Pressure (MWP) as listed above, so for temperatures above 130˚C reduce the MWP by 0.75% for each 1˚C above 130˚C. Example: at 180˚C, reduce the MWP by (180 – 130) x 0.75 = 37.5%.

Pressure Ratings above 100 Bar (1500 psi) only apply for the transfer of non-penetrating fluids. If gases or penetrating fluids are used in the application, or used during pressure testing at pressures above 100 Bar, HPG grade hose is required.

Maximum Working Pressures (MWP) listed are calculated on the basis of a 3:1 safety factor relative to the burst pressure, so Burst Pressure = 3 x MWP. If MWP is required based on a 4:1 safety factor (e.g EN 16643 requirement), multiply the listed value by 0.75.

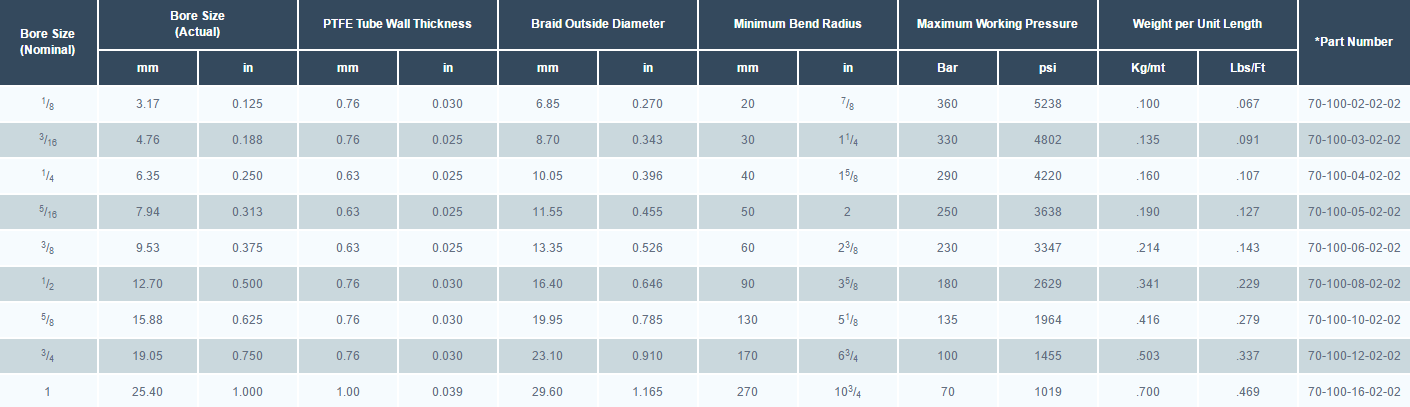

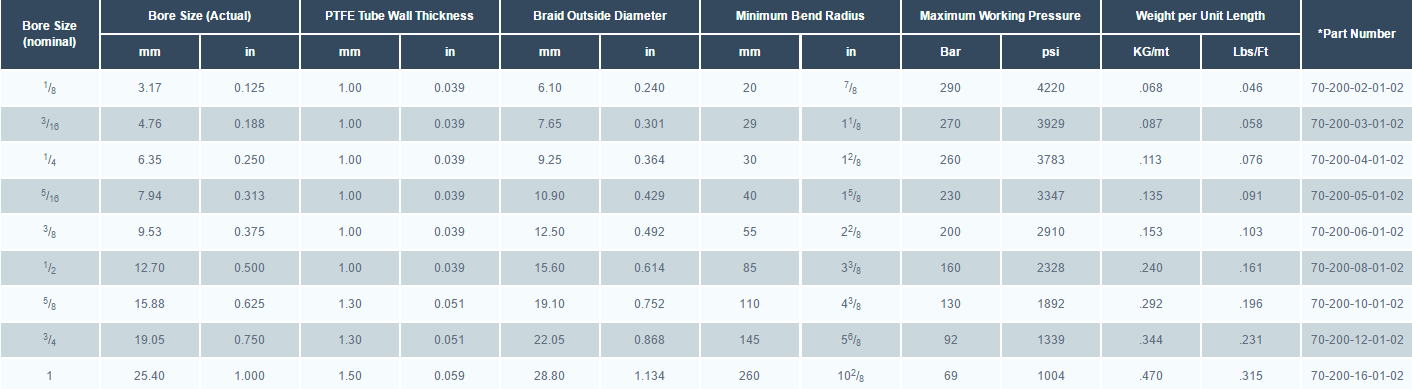

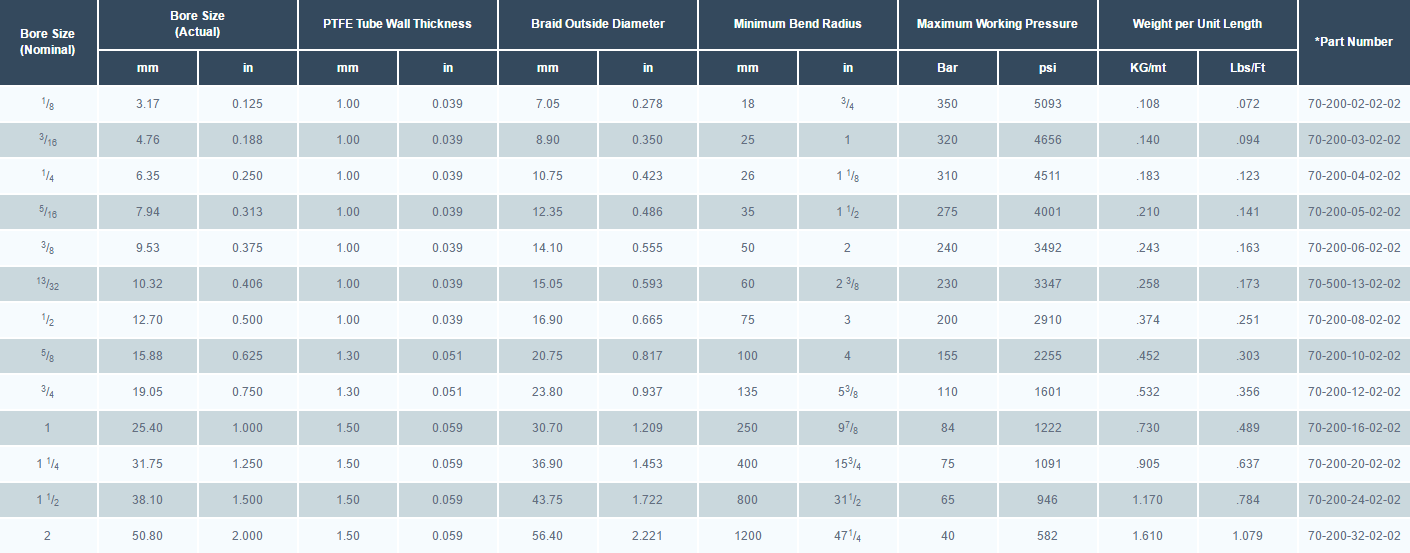

DOUBLE BRAID HOSE

Specifications and Size Range

For Double Stainless Steel wire braid hose (DB Grade) and Antistatic (AS, DB) Grade.

Standard Wall, Double Braid (SW, DB)

Heavy Wall, Double Braid (HW, DB)

Medium Wall, Double Braid (MW, DB) also referred to as Hyperline SB, DB

* For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100 becomes 70-110. For High Pressure Gas Grade, add 20, eg 70-200- becomes 70-220.

Temperature & Pressure

- Temperature affects the Maximum Working Pressure (MWP) as listed above, so for temperatures above 130˚C reduce the MWP by 0.75% for each 1˚C above 130˚C. Example: at 180˚C, reduce the MWP by (180 – 130) x 0.75 = 37.5%.

- Pressure Ratings above 100 Bar (1500 psi) only apply for the transfer of non-penetrating fluids. If gases or penetrating fluids are used in the application, or used during pressure testing at pressures above 100 Bar, HPG grade hose is required.

- Maximum Working Pressures (MWP) listed are calculated on the basis of a 3:1 safety factor relative to the burst pressure, so Burst Pressure = 3 x MWP. If MWP is required based on a 4:1 safety factor (e.g EN 16643 requirement), multiply the listed value by 0.75.

Alternative PTFE Hose Cover Design Options

Purpose

For many applications, it is required that Smoothbore PTFE hose of all sizes, grades and braids should have an outer cover of a flexible plastic, or rubber.

This is usually required to protect the braid, or to colour the hose, or to allow printing on to the hose.

Plastic Covers – available to special order

PVC – flexible PVC covers are the most popular, either transparent, or a wide range of solid or semi-transparent colours.

A particular application is for -3 size single braid, clear PVC covered hose, used as a brake hose for motorbikes, motorsport and special vehicles.

PVC covers are designated as “PVC” followed by the colour if a solid colour is required or “Trans” then the colour if a semi-transparent colour is required. PVC cover will be 0.025” (0.63mm) as standard, alternative cover thickness is available on request.

For example – “-3 HW, SB, PVC Blue” would call for a -3 heavy wall, single braid hose with a solid, blue PVC cover.

Nylon II (Nyl), Hytrel (Hyt), Sarlink (Sar) and other types of flexible thermoplastics are also widely used.

Text can be continuously printed along the hose length, usually in black.

Rubber Covers – available to Special Order

Aflex Hose also have rubber extrusion facilities, and can continuously extrude rubber covers on to all grades of hose.

EPDM rubber in blue (RC Blue) or black (antistatic) (RC Black), or platinum cured Silicone rubber in transparent (SI) or white (SI White) are available to special order. Other colours and types of rubber may also be available. Consult Aflex Hose for details. Standard thickness of EPDM/Silicone covers are 0.040” (1mm). Other thicknesses are available on request. EPDM covers are only available in sizes from 1/4” (-5).

“PRICKING” of Hose Covers

When covered hose is used in gas applications, it is always necessary to “prick” the cover at intervals, to allow the release of any diffused gas. Rubber covered hose is always pricked, but plastic covered hose is not, so pricking must be specially requested for all gas applications requiring plastic covered hose.

Colour References

If a particular grade of one colour is required, a RAL Number or a colour reference sample is required.

Note: Coloured covers are to special order, and require a Set-Up Charge, so small quantities are usually

not economic.

Limitations in Use

The application of a plastic or rubber cover limits the usage conditions of the hose, particularly the operating temperature ranges, as given below.

Flexible PVC from -10˚C (+14˚F) to +60˚C (+140˚F)

Nylon II from -40˚C (-40˚F) to +120˚C (+248˚F)

EPDM Rubber from -40˚C (-40˚F) to +140˚C (+284˚F)

Silicone Rubber from -73˚C (-100˚F) to +204˚C (+400˚F)